|

09/03/13

Macro to Introduce New “FlatPack” Coextrusion Die at K 2013

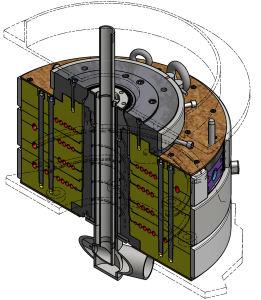

Plastic film and sheet extrusion systems supplier Macro Engineering & Technology Inc. will introduce their latest coextrusion die for extruding high barrier multilayer films at the K 2013 Trade Fair.

The new die for coextruding barrier films up to 11 layers can be used to produce structures using any barrier material including PA (Nylon), EVOH, PETG and PVdC. The optimized design of the FlatPack die, which features round flow channels throughout, streamlines the flow of polymer to optimize residence time distribution and shorten residence time. This reduced residence time virtually eliminates interfacial instability making the die more versatile for a wider range of film structures. The die also features shortened purging times,

allowing processors to perform faster product changeovers with reduced scrap generation.

“Over the past year we have revamped our extrusion die department”, states Jim Stobie, CEO at Macro. “Our objective is to provide more versatile extrusion dies to flexible film producers; dies that allow users to manufacture a broader range of products while being more reliable and with less down time. We’ve invested in our rheology and engineering personnel to drive that innovation. We’ve refocused our blown film die offering; upgraded our CenterPack die, and are excited to launch our new FlatPack die in October”.

The FlatPack die offers improvements in residence time and purging over previous Macro die designs. For

example, a 9-layer FlatPack configuration has been shown to reduce residence time up to 30% and shorten purging time by 20%. The FlatPack also gives processors the added flexibility to allow major film structure adjustments by swapping layers, such as reconfiguring a A/B/C/D/E structure to A/C/D/B/E.

The die boasts a short height and is available up to 760 mm die diameter.

|

|

About Macro

Macro Engineering & Technology is a global supplier of film and sheet extrusion systems that specializes in barrier film lines and custom engineered extrusion systems. Founded in 1978, Macro’s approach is to help film and sheet producers reach their production goals through a project-oriented philosophy and an uncompromising commitment to developing innovative technologies.

Macro manufactures blown, cast and biaxially-oriented coextrusion lines for multilayer films up to 11-layers. The company also supplies sheet extrusion lines for specialty applications, along with extrusion coating and laminating lines. Macro also specializes in developing customized winding solutions and supplies winding equipment to meet the needs of complex requirements.

Macro’s equipment is used throughout the world to manufacture value-added products in the food packaging, medical, and industrial markets.

For more information about Macro Engineering & Technology Inc. contact us.

|