Home > Blown Film > Blown Film Components > Supercom 9000

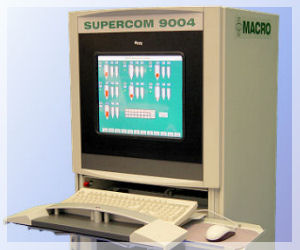

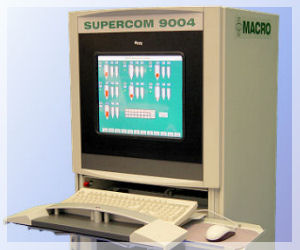

Supercom 9000 Supervisory System

Macro's SUPERCOM 9000 is a touch screen computer based supervisory and control system developed to simplify the operation of polymer processing lines. All line parameters are grouped in one display for easy access to all relevant information, allowing operators to quickly load, view, edit, save or delete set points. Parameter values present on the line are easily visualized in real time as it is running. Set points can be individually edited for one component or collectively for the whole system.

Macro's SUPERCOM 9000 is a touch screen computer based supervisory and control system developed to simplify the operation of polymer processing lines. All line parameters are grouped in one display for easy access to all relevant information, allowing operators to quickly load, view, edit, save or delete set points. Parameter values present on the line are easily visualized in real time as it is running. Set points can be individually edited for one component or collectively for the whole system.

Critical parameters for all line machinery and devices can be supervised and/or controlled. Some of the critical parameters that can be displayed and controlled with SUPERCOM 9000 include melt and zone temperatures, melt pressures, motor loads, motor speeds and web tensions.

Commands allow direct control of machine functions such as starting and stopping of extruders, winders and treating units, opening and closing of bubble cages and nips, raising and lowering of elevating mechanisms, etc.

Featured Upgrades

MacroEye Camera Monitoring System

MacroEye Camera Monitoring System

MacroEYE provides full motion, real-time video of normally unattended or hidden portions of the line through strategic placement of up to 8 stationary cameras.

Monitoring line activity can be done from on-site offices via local network connections, or remotely via Internet connections.

A portable float camera can be used to capture video of a specific problem on the line to be viewed by Macro engineers via an Internet connection for remote troubleshooting.

The SUPERCOM station, as well as other client stations, is capable of recording and playing back video. The internal storage of MacroEYE is capable of storing one week of footage from eight cameras recording for eight continuous hours per day. For lines that utilize fewer cameras, the storage time is even greater. This recorded footage may be used to create process video clips for quality and production analyses, research and development, and line maintenance purposes.

Thermal Imaging System

Thermal Imaging System

The thermal imaging system allows processors to monitor bubble temperatures from anywhere an Internet connection is available.

The system consists of one or more infrared cameras that target specific points on the bubble to monitor temperatures. The data is displayed in real-time on the Supercom HMI and stored by the supervisory system for future analyses. The system can also be used to monitor a configurable zone to provide a broader range of observation. Alarms are easily programmed to bring attention to any temperatures that fall out of the desired maximum and minimum thresholds. In addition to on-site alarm signals, an email is automatically generated with a snapshot of the screen and sent to offsite personnel for immediate notification of temperature-related problems.

The cameras can also be directed at specific line equipment, such as the die or extruders, to monitor preheating during early morning or overnight startups when supervision may be limited. If equipment temperatures reach unsafe levels the system will automatically shut down heating to avoid damage to the line.

The upgraded software allows the user to run analysis tools, set up alarms and scheduled data collection events, and adjust the cameras settings.

Macro's SUPERCOM 9000 is a touch screen computer based supervisory and control system developed to simplify the operation of polymer processing lines. All line parameters are grouped in one display for easy access to all relevant information, allowing operators to quickly load, view, edit, save or delete set points. Parameter values present on the line are easily visualized in real time as it is running. Set points can be individually edited for one component or collectively for the whole system.

Macro's SUPERCOM 9000 is a touch screen computer based supervisory and control system developed to simplify the operation of polymer processing lines. All line parameters are grouped in one display for easy access to all relevant information, allowing operators to quickly load, view, edit, save or delete set points. Parameter values present on the line are easily visualized in real time as it is running. Set points can be individually edited for one component or collectively for the whole system.